With the rapid development of my country’s railway transportation industry, higher requirements are put forward for the daily maintenance, equipment maintenance and fault diagnosis of railway diesel locomotives. Oil analyzers play an important role in the monitoring and diagnosis of railway diesel locomotives.

According to relevant research data reports, more than 70% of mechanical equipment failures are caused by wear and tear. About 1/3~1/2 of the energy produced in the world is consumed by friction loss. With the rapid development of modern industry, how to ensure the safe and stable operation of machinery and equipment, reduce the occurrence of failures and reduce maintenance costs has become a problem that must be solved. On the basis of scientific and reasonable lubrication technology, the establishment of mechanical equipment wear condition monitoring and fault diagnosis technology has significant social and economic benefits. Oil analysis is one of the most effective non-destructive monitoring methods.

Oil analyzers have been used for a long time in the monitoring and application of railway internal combustion engines. The early oil analyzers only routinely analyzed the physical and chemical indicators of new and in-use lubricating oils, which was very simple. With the rapid development of railways, railways are developing towards heavy load, high speed, automation and high efficiency. Maintenance costs and downtime losses for diesel locomotives have also increased dramatically. The traditional planned maintenance method has high maintenance costs. It cannot maximize the efficiency of locomotive use. The railway system has gradually introduced advanced oil analysis instruments such as chromatography, spectroscopy and ferrography.

These instruments have the advantages of simple operation, convenient diagnosis, high efficiency and accurate results. It has been widely used in the field of internal combustion engine fault diagnosis. However, due to the differences of various diesel locomotives in structural design, manufacturing process, raw material materials, etc. There is no uniform standard for the characteristic parameters of various oil analyzers in fault diagnosis. This brings great inconvenience to the oil monitoring personnel and locomotive maintenance personnel in the locomotive depot. It also seriously affects the accuracy of fault diagnosis by means of oil analysis.

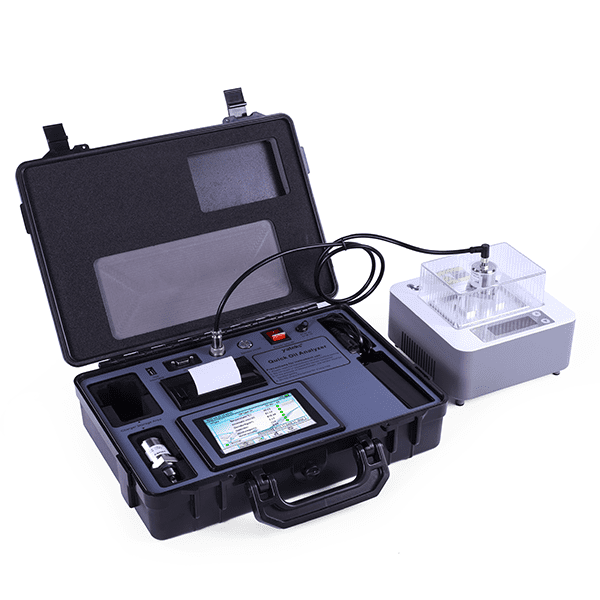

Yateks recommends two oil analysis products independently developed and produced by Yateks

Let’s take a look at the content and methods of commonly used oil analysis:

Contents of analysis: number, size distribution, composition and shape/type of abrasive particles Analysis methods: ferrography, emission spectroscopy, particle counting, etc. Goal: Identify major wear locations, degree of wear and mechanism/cause

-

Oil deterioration and pollutant analysis

Contents of analysis: oil deterioration and types and quantities of pollutants Analysis methods: infrared spectroscopy, emission spectroscopy, ferrography and other methods Objective: To determine oil availability and related system failures and causes

-

Analysis of conventional physical and chemical indicators

Contents of analysis: viscosity, flash point, moisture, total base value/acid value, etc. Analysis method: viscosity/flash point/moisture meter, titration method, spot test, etc. Objective: To determine oil availability and related subsystem failures and causes

The role of oil analysis and diagnosis technology

- Basic tools for condition-based maintenance and risk detection

- Lubrication, wear and related fault diagnosis

- Determine the best lubricant (lubricant/grease)

- Realize lubrication monitoring and determine a reasonable oil change interval

- Extend the overhaul interval and reduce equipment maintenance costs