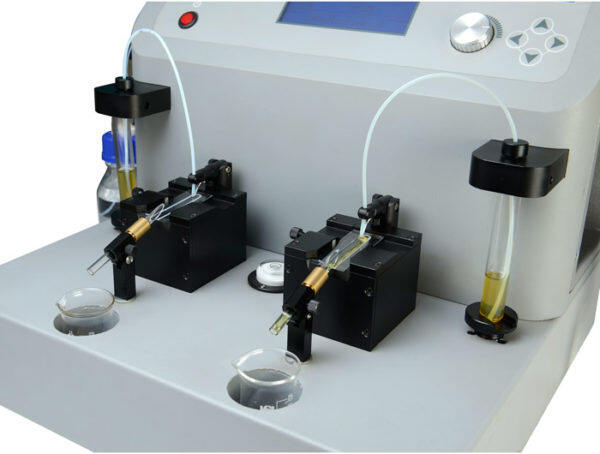

YTF-8 Dual Slide Oil Analytical Ferrography system is composed of Dual Slide ferrograph, ferroscope and ferrographic software management system. The Dual Slide ferrograph applies high-gradient magnetic field to separate the ferromagnetic and paramagnetic abrasive grains from the engine oil which will deposit on a glass sheet in an order of the size of the grains to make a ferrograph which will be observed and analyzed in many aspects like shape, size, gradient and quantity of the abrasive grains on the glass sheet by a ferroscope.

With the help of ferrographic software management system, the system can build a database for routine management and analysis of the ferrographs. The Dual Slide ferrograph can be used to check the abrasion of the internal combustion engines, gas turbines, gearboxes, bearings, hydraulic systems, etc. in many industries. Besides, it can also be used as a research tool for tribology and wear analysis in universities and scientific research institutes.

YTF-8 Oil Analysis of Dual Slide Analytical Ferrography

Features:

Specification

| MEASUREMENT RANGE | |

|---|---|

| Moisture Content | 0‐5% 0‐10% 0‐20%(optional) |

| Measurement Accuracy | 0.3%(typical)0.5%(max) |

| Resolution | 0.1% |

| Temperature | ‐40‐120℃ |

| Measurement Accuracy | 0.3℃(typical)0.5℃(max) |

| Resolution | 0.1℃ |

| Other Parameters | |

| Output | 2lines: 4‐20mA analog signal and RS485 digital signal |

| Working Voltage | DC9V‐28V |

| Working Current | < 6mA+ load current |

| Max Pressure | < 100bar |

| Working Temperature | ‐40‐85℃ |

| Oil Temperature | ‐40‐120℃ |

| Machine Interface | G1/2” BSP |

| Electrical Interface | M8*1, 6 cores |

| Cable Specification | 6 cores, UL208666*22AWG 2m |

| EMC standard | EN 61000‐6‐4:2007 EN 61000‐6‐2:2005 |

| Probe Material | stainless steel 316 |

| IP Rating | IP66 |

| weight | 250 g |

Accessory

|

Shipment

Package dimension: 580*560*610mm

Gross Weight: 28.5kg

Yateks is a world-class supplier of industrial non-destructive testing (NDT) equipment for equipment fault diagnosis and condition monitoring. Committed to manufacturing high-quality remote visual inspection tools (RVI) and oil analysis equipment for industries such as aviation, automotive, oil&gas, power generation etc.